SOLID WOOD: A BUILDING MATERIAL WITH BENEFITS

Solid wood is just that, nothing but real, natural wood through and through

Every Junckers floorboard is made of strong and durable solid hardwood – there are no layers of inferior quality; there is no glue or chemical substances in the flooring which adversely affect the air quality in a room and no reliance on fossil fuel derived materials.

We manufacture all our floors in our own factory outside Copenhagen. Every part of the tree is used in the production; what is not used for flooring is sold to the on-site power station, who uses our surplus wood to generate biomass energy for our factory and the local grid. We use large sections of wood for our floors, which means less waste, lower energy consumption, minimal use of adhesives and full recycling capabilities as the wood is not contaminated. We do not increase the overall quantity of carbon because we do not use energy and materials that are derived from fossil-based sources.

In contrast to concrete and steel, the other most widely used construction materials, using wood is good for our climate. Wood comes from a renewable and sustainable source. A single mature tree absorbs carbon dioxide at a rate of 54 kilograms per year. In one year, a hectare of forest can absorb twice the CO2 produced by the average car's annual mileage. With that 54 kilograms decrease of carbon in the atmosphere, the risk of climate change decreases drastically.

Trees have a natural ability to absorb carbon from the atmosphere and store it. As trees age, their ability to absorb carbon from the air slows. When a tree eventually dies and decomposes, it lets the carbon it has been storing back into the atmosphere. Therefore, only growing trees to store carbon is not enough. To be sustainable, we must grow AND harvest trees. A felled tree will no longer remove carbon from the air, but it will continue to store the carbon that it previously removed.

THE GREENEST CHOICE

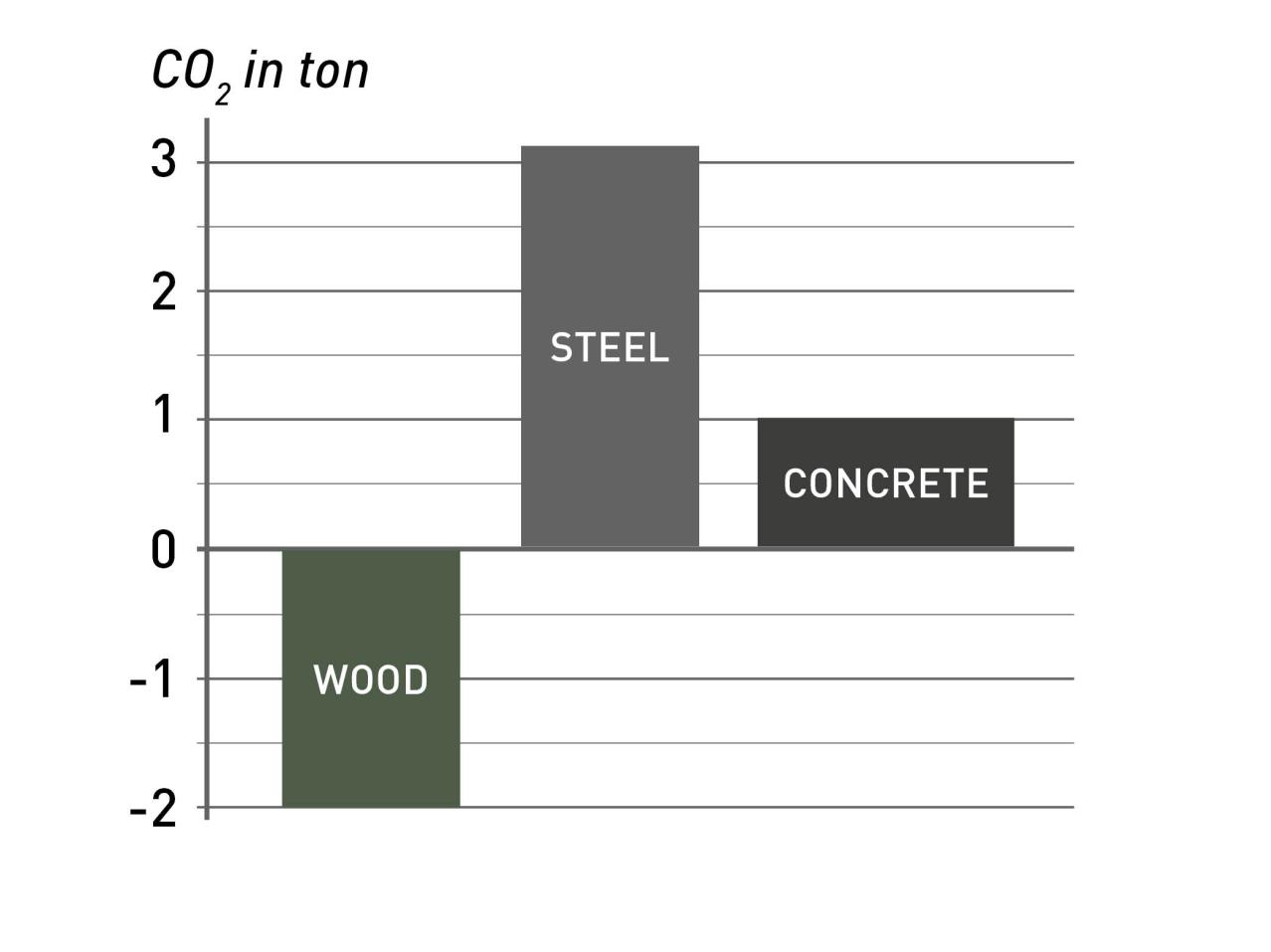

Building materials such as concrete and steel emit a lot of CO2 during production. Instead of emitting CO2 wood absorbs it while growing. This infographic offers a clear visual representation of why it is so important to use wood as a building material compared to other building materials.

Using wood instead of steel or concrete benefits the climate in two ways. Approximately one tonne of CO2 is stored in one m³ of wood. In addition, wood production requires less CO2 than the production of steel and concrete; an average of one tonne of CO2 is saved in the production of a similar product made of wood. In this way, using wood saves two tonnes of CO2 emissions when one m³ of wood replaces one m³ of concrete or steel.

Source: https://www.trae.dk/artikel/ny-folder-trae-er-genialt/#4

JUNCKERS IS HIGH QUALITY AND NATURAL SOLID HARDWOOD

Junckers floors are manufactured with care, without the use of chemicals, layers of inferior quality wood or fossil fuel derived materials. This means that Junckers floors are also more sustainable, carbon neutral and better for the environment compared to many other floors

During a presentation about the sustainability of solid hardwood flooring, Richard Aylen, UK technical manager, explains why Junckers floors have such a long lifespan.

For the full presentation click here

LIFE CYCLE

Junckers floors have an incredibly long life span, often in excess of 60 years. This means the lifetime cost of a Junckers floor is very low. A Junckers solid hardwood floor will retain its strength and high quality throughout its life, even if the floor is refurbished many times.

As well as the obvious financial benefits, a floor with a long life cycle is also beneficial to the environment. The longer a wooden floor remains in use, the longer it will store embodied carbon within the product. It will not contribute to landfill, and it will save carbon-generating energy which would have been needed to manufacture and transport replacement flooring.

The reason a Junckers floor has such a long life span is because it can be sanded up to eight or even ten times without losing quality or performance. Each time the floor is sanded and refinished it is given a new lease of life, prolonging its lifespan.

VERSATILITY

Solid hardwood floors are strong, durable, and versatile. The same hardwood timber is used to manufacture Junckers floors installed at airports and busy shopping centres as for dance studios and large arenas used for world class sport events. Hardwood is a tough, long-lasting surface which is also easy to repair.

At times we encounter clients who are worried about damaging their floor if they are using it in a new or different way. For example, a sports floor installed in a school hall can also be used for open days or exams without causing damage, despite placing chairs and tables on the floor. A further example is found in community halls, where the owners tend to give their floors a harder time by getting as much use out of the floor as they can. Despite being put through its paces; a solid hardwood floor will last for decades given the proper care and maintenance.

Eventually the floor will show signs of wear and tear, but solid hardwood floors are quite hard to destroy and can be refurbished many times over. In the medium-term, the surface will be protected by maintenance coats of lacquer which see off the effects of minor damage and foot traffic for many years.

So do not be too scared to make use of your hardwood floor. It will take some hard treatment, it is designed to do so, and when the battle scars appear, you can refurbish it…time and time again.

HUMIDITY

Junckers solid hardwood floors cannot delaminate and are designed to work within the normal humidity range for occupied buildings in your region, something our technical representatives can advise on. Whereas some engineered wood floors are known to delaminate or split due to changes in humidity levels.

We know some engineered wood flooring manufacturers recommend no more than a 20% range of humidity for their floors compared with the 30% range recommend by Junckers. This means a Junckers floor is more stable than a floor which is limited to a narrower humidity range.

Monitored through strict quality control procedures, our floorboards are carefully manufactured to ensure the wood has a low and consistent moisture content. For our beech flooring, we use our specially developed press drying process which gives our floors:

- Improved dimensional stability - reduced seasonal expansion and shrinkage

- Improved hardness - press drying permanently ‘compresses’ the wood

- Improved structural strength - simply a stronger floor that will take higher loads

- Improved uniformity of colour

The high level of stability of our floors is demonstrated by the fact that we guarantee them for use with underfloor heating.

EASY TO RECYCLE

Because Junckers floors are made of pure solid hardwood, they are easy to recycle. You can reuse planks from solid wood floors in many different ways. If the planks are still in good condition, they can be reused as flooring, or as building material for other purposes, such as wall cladding, cupboard doors, tabletops or more. If the floor has reached the end of its long life, the floorboards are biodegradable, meaning they will decompose naturally without harming the environment.

WOOD IS NATURE'S STROKE OF PURE GENIUS

It has the ability to absorb carbon from the air and store it, it is easy to recycle and it can be used for various purposes. Grow your knowledge on wood.